How to Create Custom Molded Glass Bottles for Your Brand

A step-by-step guide for brand owners on the entire process of designing, prototyping, and manufacturing custom molded glass bottles for your products

Required Materials

- High-purity glass raw materials (silica sand, soda ash, limestone, dolomite) with low iron content for clear glass

- Custom bottle mold designs (CAD files, 3D renderings, and technical blueprints)

- Custom label materials (vinyl, paper, or embossed/debossed glass finishes)

- Color pigments (for tinted glass) or coating materials (matte, glossy, metallic)

- Closure materials (cork, aluminum, plastic, or custom glass stoppers)

Required Equipment

- CNC machining equipment for precision mold manufacturing

- Glass melting furnace (operating at 1500°C for optimal glass viscosity)

- IS machine (Individual Section Machine) for automated bottle forming

- 3D printers (for resin/plastic prototypes) and 3D scanners (for design validation)

- Quality control tools (calipers, thickness gauges, impact resistance testers)

- Surface treatment equipment (sandblasters, silk-screen printers, coating lines)

Custom Manufacturing Process Steps

Design Concept & Consultation

You provide initial design concepts, including desired volume (e.g., 750ml for spirits, 500ml for beverages), shape (cylindrical, square, custom contours), and aesthetic style (minimalist, vintage, premium). Our team of industrial designers and glass engineers will review your requirements, provide feasibility assessments, and refine the concept to align with manufacturing capabilities and industry standards. We also discuss regulatory compliance (e.g., food-grade glass requirements) and sustainability goals (recyclable materials, energy-efficient production).

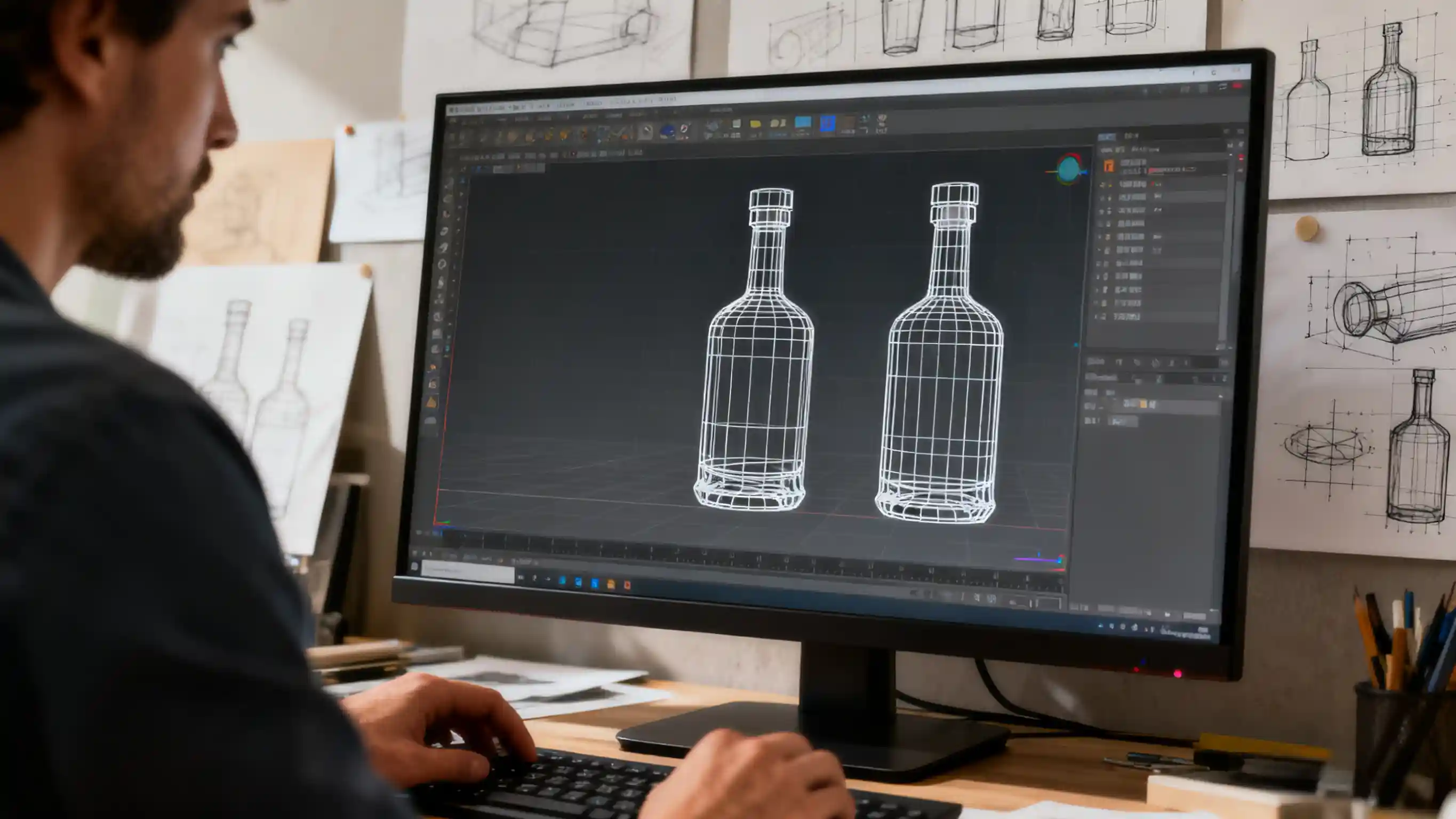

3D Technical Drawings

Based on the approved design concept, our engineering team creates precise 3D technical drawings using CAD software (SolidWorks, AutoCAD). These drawings include detailed specifications: wall thickness (typically 2.5-4mm for glass bottles), neck finish dimensions (to fit closures), base structure (for stability), and tolerance levels (±0.1mm for critical dimensions). The 3D model serves as the master blueprint for prototyping and mold manufacturing, and we share interactive 3D previews with you for final design validation before physical prototyping.

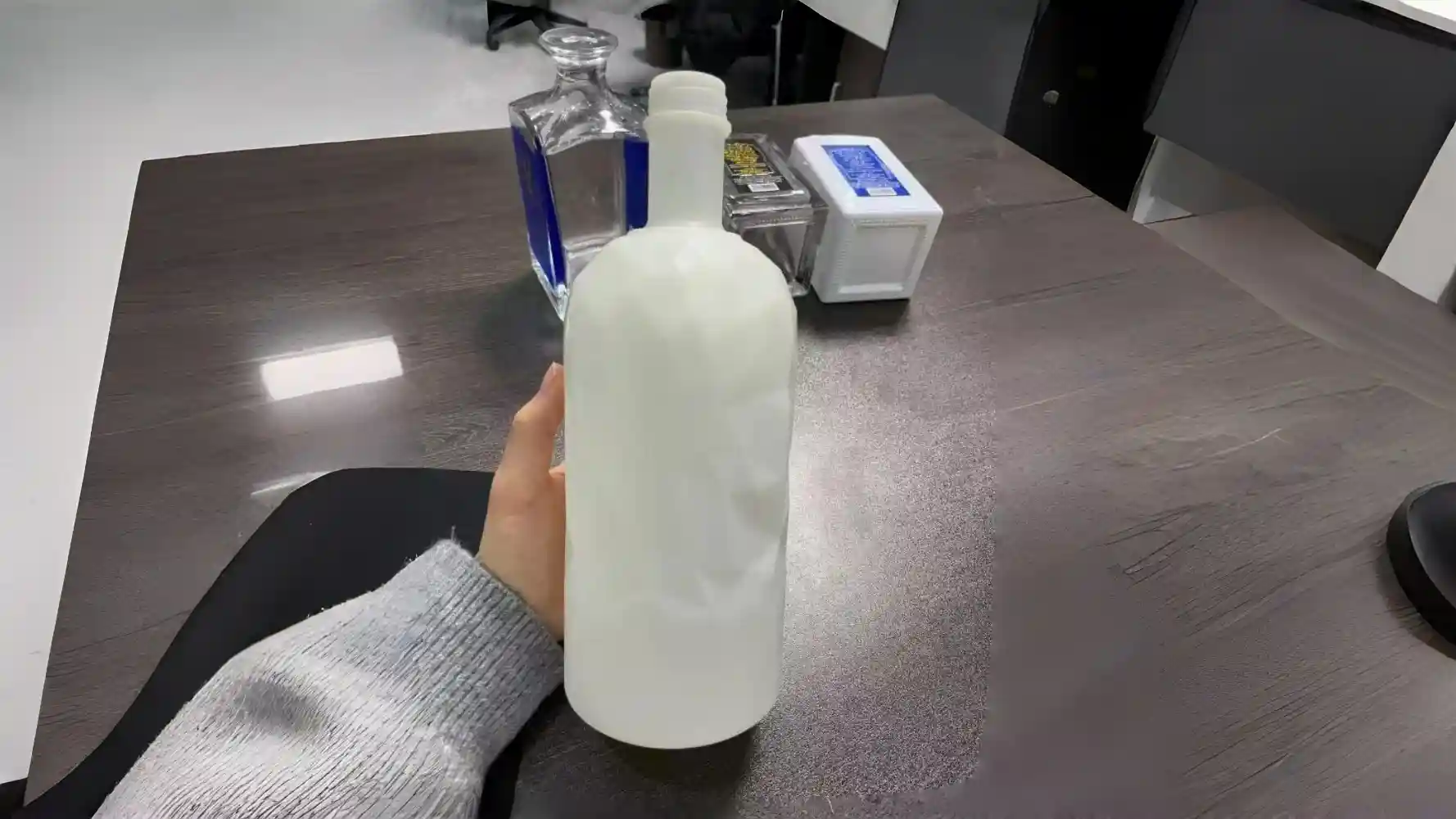

3D Prototype Sampling

We produce physical 3D prototypes (typically made from food-grade resin or durable plastic) directly from the technical drawings using industrial-grade 3D printers. This prototype is a 1:1 scale replica of the final glass bottle, allowing you to physically hold, test, and evaluate the design's ergonomics (e.g., grip comfort), visual proportions, and functional aspects (e.g., pour spout flow). We provide up to 2 rounds of prototype revisions to address any design adjustments before moving to mold production, minimizing costly changes later in the process.

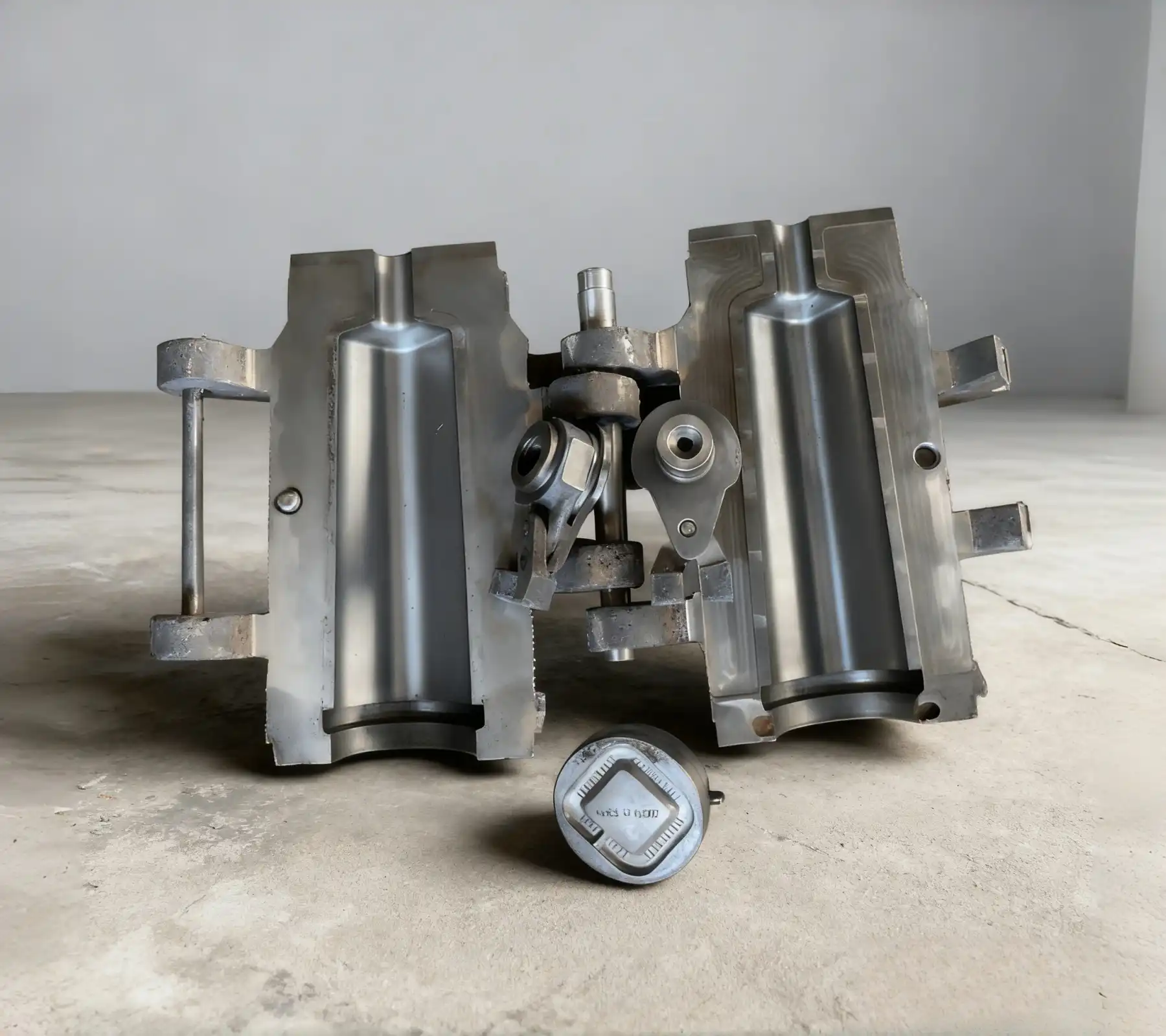

Mold Fabrication & Glass Sample Production

Upon your approval of the 3D prototype, our precision machining team fabricates high-grade steel molds (H13 tool steel for durability) designed to withstand repeated high-temperature glass forming cycles (up to 1 million cycles for standard molds). The mold manufacturing process takes 2-3 weeks and includes CNC milling, polishing, and heat treatment for longevity. We then produce a small batch (10-20 pieces) of glass samples using the new mold, testing for dimensional accuracy, surface finish, and structural integrity (e.g., resistance to thermal shock). These glass samples are sent to you for final confirmation of appearance, size, and quality before full-scale production.

Mass Production

Once the glass samples are approved, we initiate full-scale production using our automated IS machines, which can produce up to 1,200 bottles per hour per mold cavity. The production process follows strict quality control (QC) protocols: raw material testing (glass batch composition), real-time monitoring of furnace temperature, in-line dimensional checks, and visual inspection for defects (bubbles, cracks, uneven walls). Our QC team inspects 1 out of every 50 bottles during production, and we maintain a defect rate of less than 0.5% for standard orders. Production lead time varies by order volume: 2-3 weeks for small batches (10,000 units), 4-6 weeks for large orders (100,000+ units).

Surface Finishing & Decoration

After the base glass bottles are formed, we apply custom surface treatments and decorations per your specifications. Options include: color coating (water-based or solvent-based coatings for matte, glossy, or metallic finishes), sandblasting (for frosted/matte effects on specific areas), acid etching (for permanent, high-end logos or patterns), silk-screen printing (up to 6 colors for detailed graphics), hot stamping (gold/silver foil for premium branding), and embossing/debossing (3D texture on the glass surface). All finishing materials are food-safe and compliant with FDA/EU regulations for beverage contact. We conduct adhesion tests on coated surfaces to ensure durability during transportation and handling.

Closure Production (Caps/Corks)

We manufacture or source custom closures that perfectly match your bottle's neck finish and design aesthetic. Options include: natural cork (for spirits/wine), synthetic cork (for longer shelf life), aluminum screw caps (with tamper-evident seals), plastic flip-top caps (for beverages), and custom glass stoppers (for premium products). All closures are tested for airtightness (to prevent oxidation of contents) and compatibility with the bottle's neck dimensions. For branded closures, we offer laser engraving, embossing, or printed logos to align with your brand identity. We also provide closure assembly services (attaching caps/corks to bottles) if required.

Packaging & Shipping

Finished custom glass bottles (with closures) are carefully packaged to prevent damage during transit. We use eco-friendly packaging materials: corrugated cardboard boxes with custom foam inserts (for small batches), or bulk packaging (divided cartons or palletized stretch wrap) for large orders. Each package includes shock-absorbent padding and is labeled with handling instructions (e.g., "Fragile," "Keep Upright"). We offer multiple shipping options: sea freight (cost-effective for large orders, 4-6 weeks transit time), air freight (fast delivery for urgent orders, 3-5 days), or local delivery (for regional customers). We provide full shipping documentation (commercial invoice, packing list, certificate of origin) and track shipments until delivery to your facility, ensuring on-time arrival and zero damage (we offer a damage replacement guarantee for standard shipments).

Start Your Custom Bottle Project

Ready to create your unique custom glass bottle? Our team of designers and engineers will guide you through every step of the process, from concept to delivery. We specialize in high-quality, sustainable glass packaging for spirits, beverages, cosmetics, and luxury products.

Contact Our Team